STRUCTURAL REINFORCEMENT

STRUCTURAL REINFORCEMENT

RODRÍGUEZ ROS

At Rodriguez Ros, a building rehabilitation business in Malaga and Andalusia, our experience in structural reinforcement is extensive. Sika Carbodur carbon fibre sheet and Sikawrap carbon fibre fabric systems that we put at the service of our Clients. These systems are lightweight and allow a very fast installation on the structure.muy rápida.

STRUCTURAL REINFORCEMENT WITH CARBON FIBER SHEETS

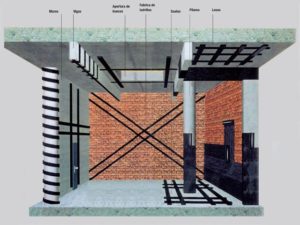

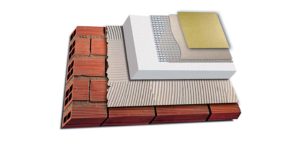

The reinforcement of structures by carbon fibre sheets is widely used for the reinforcement of bending or shearing building structures of beams, slabs, pillars, etc… Significantly increasing the safety coefficients and bearing capacity of the elements of the structure with a minimum contribution of carbon fibre. At present, technical calculators are highly accustomed to the design and calculation of structural reinforcements with sheets of carbon fibre, being accepted as systems of reinforcement of structural elements. Rodriguez Ros uses Sika structural reinforcement system with Sika carbon fiber sheets. This is a High Technology Reinforcement that includes FRP laminates and epoxy resin as a structural adhesive and are applied directly on site. Other of our important related services in the restoration of buildings is the waterproofing of terraces and roofs or the repair of concrete.

APPLICATIONS OF STRUCTURAL REINFORCEMENT

ACCORDING TO RODRIGUEZ ROS

LOAD INCREASES

Increase of the resistance capacity in slabs and beams. Increased bridge capacity to withstand increased axial loads. Heavy machinery installation.

DEFECTS OF THE PROJECT OR ITS EXECUTION

Insufficient dimensions of the structural elements. Insufficient or wrongly placed reinforcements. Poor arrangement of the structural elements. Low quality materials.

RENOVATION OF OLD STRUCTURES

Awareness of the weaknesses of the calculation method used. Consideration of reinforcements against dynamic solicitations. Aging of materials with loss of their initial characteristics. Adaptation of the initial project to more demanding new standards.

- Changes in the shape of the structure itself: Opening of holes in slabs. Elimination of pillars or load-bearing walls.

- Damage in the structure: Impacts on the structure. Fires. Corrosion and loss of concrete reinforcement section. Earthquake.

- Need for improvement in the conditions in service: Reduction in tension of the reinforcement. Decrease in deformations and deflections, using high modulus laminates.

- Seismic and anti-earthquake reinforcement: An important field of application is to wrap the pillars to prevent premature failure in the event of an earthquake. The SikaWrap fabric made with carbon fibres is the most suitable for its modulus of elasticity.

MORE BUILDING REHABILITATION SERVICES:

GLOSSARY

Confinement: This method is applied to elements that are subjected to compression, with the main goal of improving load-bearing capacities or to improve resistance against earthquakes or seismic events by enhancing its creep. Sikawrap composites are highly reliable materials used for the reinforcement of concrete structures.

Shear reinforcement: The flexibility of the Sikawrap fabric allows it application on irregular sections in pillars and reinforced concrete beams. The combination of shear reinforcement with high modulus carbon fabric coupled with flexion reinforcement with Sika Carbodur sheeting is optimal.

Reinforcement against impact: The SikaWrap fabric, which is made of aramide fiber, can absorb high levels of energy caused by the impact of a car and can therefore protect the pillar from collapse.

Flexion reinforcement: Flexion reinforcement cannot only be applied using SikaCabroDur sheeting, but also with SikaWrap fabric, especially when the support strength is low. Special attention must be paid to the correct alignment of the fibers, particularly in the case of very long lengths of reinforcing material.

Properties: Reduction of crack openings. Fatigue reduction. 1.2M fibers in S512 Sika CarboDur sheeting. Fiber volume content > 68%. Ø = 5-7mm μm. Easy handling. Unidirectional material. LFibers are parallel to loads only in the longitudinal direction. Great tensile strength. Sheer and flexion reinforcement.

Great tensile strength, non-corrosive, great fatigue strength, low weight, easy application, thermal coefficient near to zero, no ductile level.

Structural design according to FIB (Fédération International du Béton) recommendations.

Sika CarboDur and SikaWrap vs. steel sheeting: Unlimited lengths. Easy application. Low-weight sheeting. Easy crisscrossing. Thin sheets (1.2 – 1.4 mm). Low cost of application. No corrosion with Sika CarboDur sheeting.