Joint Sealing

RODRÍGUEZ ROS

Joint sealing systems prevent air and water from penetrating inside buildings and therefore, prevent damage to homes. Joint sealing products must meet several requisites depending on their fuction and location with respect to the joint: prevent the entry of elements (air, water, chemicals, smoke, etc.), improve thermal and acoustic insulation and improve construction aesthetics.

Temperature changes cause expansion and contraction movements in building elements. For example, joints become larger (expand) or smaller (contract) continuously. Movements due to thermal changes can be significant in the case of large elements or when materials of different nature are used.

These movements are caused by the settling of the structure, vibrations and other loads (wind, etc.) that deform the dimensions of the joint and exerting a considerable pressure on the sealed material. Structural movements normally lead to shear stress on the sealer.

For this process, Rodríguez Ros uses elastic seals, which, compared to rigid materials (e.g. mortar or cement) accompany thermal and structural movements without breakage or loss of adhesion to adjacent construction elements. These sealants maintain their properties during their entire lifecycle, providing long-term sealing.

Rodríguez Ros applies Sikaflex, Sikasil, Sikacryl, Sikadur Combiflex polyurethane sealing systems. These are polyurethane systems that are designed for a broad variety of applications including joints in pre-fabricated concrete facades, joints in glass and metal facades, natural stone facades, joints in ventilated faces and envelopes, joints in pavements and parking lots, joints in roofs, joints in interior finishings, joints in bathrooms, kitchens, etc.), joints in swimming pools, joints in retaining walls (gas stations, etc.), submerged joints or joints in waste water treatment plants, joints in clean rooms (photovoltaic industry, electronics industry, pharmaceutical industry, etc.), joints in drinking water tanks (British Standard 6920. Contact with drinking water).

- Sealing application with Sikadur Combiflex System: Rodriguez Ros installs a highly effective joint sealing system consisting of a Sika Combiflex sealing strip (flexible and waterproof polyolefin FPO strip) and Sikadur epoxy adhesive. This system has a proven effectiveness in sealing joints and/or cracks in all types of watertight or retaining structures. It is particularly suitable for the construction of watertight basements, facades, floors and can be applied both indoors and outdoors in order to meet the requirements of the project. When fixed to the substrate it allows large and irregular movements in more than one direction while maintaining a high quality sealing system for expansion, construction or connection joints as well as for cracks and crevices in: Tunnels and galleries. Hydroelectric plants. Waste Water Treatment Plants. Foundations. Drinking water tanks and water retention structures. Around iron, steel and concrete pipes. Swimming pools. Joints with extreme movement. In building joints that exceed the expected dimensions. Joints and cracks.

- In the manufacturing and food industries, Rodriguez Ros uses sealants that withstand forklift traffic and cleaning machinery, can be cleaned with pressurised water, withstand cleaning with aggressive cleaning products and other chemicals, and are compatible with foodstuffs.

- The sealants for joints in car park pavements are resistant to road traffic loads and machinery with cleaning products, retain their properties in direct contact with oils and fuels, withstand weathering in outdoor applications.

- The sealants that Rodriguez Ros applies in pedestrian areas such as train stations or shopping centres have Shore A hardness, maintain a high mechanical strength throughout its surface while maintaining the aesthetic appearance and uniform colour, are resistant to cleaning liquids and high pressure cleaning.

- ISO 11600 25 HM. Aprobación ISEGA para la compatibilidad con los alimentos. Material apto para salas limpias CSM. ISO 11600 25 HM. EN 15651, parte 4 25 HM. Aprobación ISEGA para la compatibilidad con los alimentos. ISO 11600 12.5 E. EN 15651, parte 4 12.5 E.

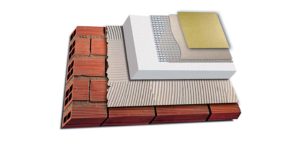

- In all roofs of buildings, hotels, industries, etc… it is necessary to seal different joints, e.g. between the parapet and the slab or joints around skylights or between different waterproofing sheets. Rodriguez Ros applies polyurethane sealants with excellent adhesion to porous and non-porous substrates, excellent compatibility with roof waterproofing membranes and good adhesion to them, high resistance to UV and weathering.

- ISO 11600 F 25 HM. ASTM C 920 Class 50. SNJF Façade 25 E. EC1 very low emissions.

- The sealants that Rodriguez Ros applies in wastewater treatment plants withstand extremely severe conditions and meet high requirements: Durability and good adhesion despite remaining permanently submerged in water, high mechanical strengths to withstand strong water currents, resistance to wastewater treatment chemicals and microbiological attack.

- ISO 11600 25 HM. Tested according to the specifications and principles of the DIBT (German Certification Body for Building Products) for exposure to waste water. Tested according to the recommendations of the DIBT Guide (German Certification Body for Building Products) for exposure to waste water. Resistant to liquid fertilisers. Resistant to composting. ISEGA Certified for food contact. Tested to BS 6920 (contact with drinking water).

Gasket sealing application for retention basins and petrol stations: With resistance to fuel oil and oils. High resistance to various chemicals. High mechanical strength. Comply with current regulations and tests. - (ETA-09/0272) European Technical Approval as a joint sealing system for storage, filling and handling of polluting liquids.

- Airport sealing application: Adhesion and flexibility at any temperature. Resistance to heavy traffic from aircraft, maintenance vehicles and trucks. Resistance to chemical attack. US Federal Specifi cation SS-S-200E.

- Application of seals in tank and silo joints: High resistance to acids, especially organic acids. Resistance to liquid fertilisers. Resistance to waste water. Resistance to fermentation liquids inside the silo.

- Tested according to the specifications and principles of the DIBT (German Approval body for construction) for exposure to waste water. ISEGA certified for food contact. Conforms to BS 6920 (contact with drinking water).

- Swimming pool joint sealing application: Excellent UV resistance and stability. High resistance to chlorine. High durability even when permanently submerged. Resistance to fungal and mould growth.

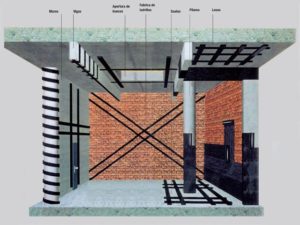

- Application of fireproof joint sealants: Comply with local regulations. Possess high ignition resistance and low flame spread characteristics. Prevent the passage of smoke through the mastic. Maintain the seal properly for as long as possible while subjected to fire.

- BS 476-20. DIN 4102 B1. ISO 11600 25 LM. ASTM C 920 Class 25 BS 476-4 (combustibility test).