External Thermal Insulation Composite Systems (ETICS)

External Thermal Insulation Composite Systems (ETICS)

RODRÍGUEZ ROS

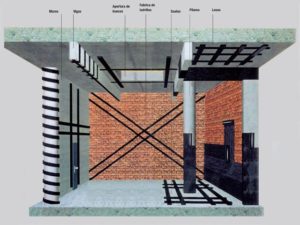

Rodríguez Ros is a company that applies and installs seismic systems, seismic isolators or anti-earthquake (anti seismos) for reinforcement, fastening and anchoring of: Walls, masonry, partition walls. As specialists in the rehabilitation of buildings and facades, we offer a seismic isolator service.

ENERGY EFFICIENCY IN SATE INSULATION WITH SIKA

If we seek to obtain energy efficiency in a building, we must obtain an ideal thermal insulation. The goal of Sika’s ThermoCoat External Thermal Insulation Composite Systems (ETICS) is to reduce energy consumption in newly-constructed buildings and also in the rehabilitation of existing ones.

WHAT DOES EXTERNAL THERMAL INSULATION CONSIST OF?

The External Thermal Insulation System (SATE Malaga) saves buildings on electricity bill costs as most of the buildings constructed have very poor or insufficient thermal insulation. Even more so in buildings that are more than 20 years old, which have insufficient SATE energy insulation.

ENERGY SAVINGS THANKS TO EXTERNAL THERMAL INSULATION

Improving the thermal insulation of a building means energy savings of 30-35% or more in many cases in heating and air conditioning consumption due to the reduction of losses, with the consequent reduction of CO2 emissions into the atmosphere.

Thermal insulation achieves:

Energy savings

Cost reduction

Improving healthy conditions

Respect for the environment

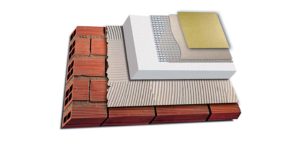

The installation of the SATE is especially indicated in the case of building renovation, as it allows the insulation problem to be easily solved without having to carry out works inside the homes, thus avoiding inconvenience to the owners.

INSTALLATION PROCEDURE SATEATE INSTALLATION PROCEDURE SATEATE INSTALLATION PROCEDURE

Installation of the insulation panels (expanded polystyrene (EPS)) are fixed to the external walls of the building with adhesive mortar and mechanical fasteners. After reinforcement with mesh, the decorative exterior cladding is applied.